Consulting . Research . Outsourcing . Technology

Abrasion Resistant Silver

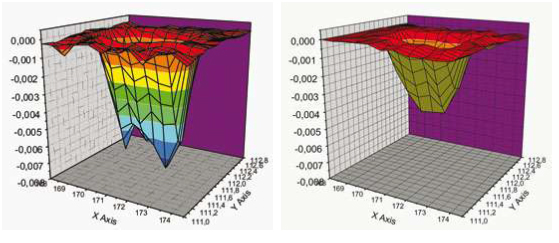

Wear scratch profile of standard silver (left) and of nano diamond additive-Silver(right)

Silver coatings are often used to increase the conductivity and corrosion stability of copper in electrical connectors, switches, circuit boards etc. In electroplating, silver is primarily used in industrial applications, especially for the power generation and distribution equipment. Even in telecom, automotive, jewelry and cutlery silver is widely used as a finishing material. The main drawback of silver is its poor mechanical stability and high friction coefficient. Finding a solution to reduce wear and friction is therefore of exceptional interest.

Nano diamond based additives lead to the formation of smaller metal crystallites (and a smaller distance between crystallites) during the electroplating process. As a consequence, the elasticity, abrasion resistance and hardness of the metal increase and friction coefficient decreases. The amount of nanoparticles getting co-deposited with the metal is tiny (below 0.1%), nevertheless, their presence decreases both wear and friction coefficient by 60%. Simultaneously, the electrical conductivity of silver remains unaltered. By using these novel additives, one can either increase the life-time of the final device, or reduce the thickness of the plating, and therefore the consumption of silver by 2-3 times.

Advantages

Contact us to know more about this technology